The government and automotive industries are pushing hard toward zero-emission mobility, yet the road to electrification is proving more complex than many expected. Bodyshops, repairers, insurers and claims professionals are already dealing with the real-world consequences: higher repair costs, longer cycle times, specialist labour, extensive ADAS calibration, and the growing burdens of EV quarantine, power-down procedures and re-energising protocols, as outlined clearly in the ABP 2026 Repair & Retail Charges Guide.

At the same time, drivers and fleet decision-makers are feeling the pinch. Rising public-charging tariffs, congestion-zone fees, ULEZ expansion, pay-per-mile proposals, and increased Benefit-in-Kind for many electric vehicles mean the “cheap to run” narrative is becoming harder to maintain. Add in the practical challenges like limited charging infrastructure, longer downtime during repairs, cold-weather range loss, etc and momentum towards BEVs is slowing in parts of the market.

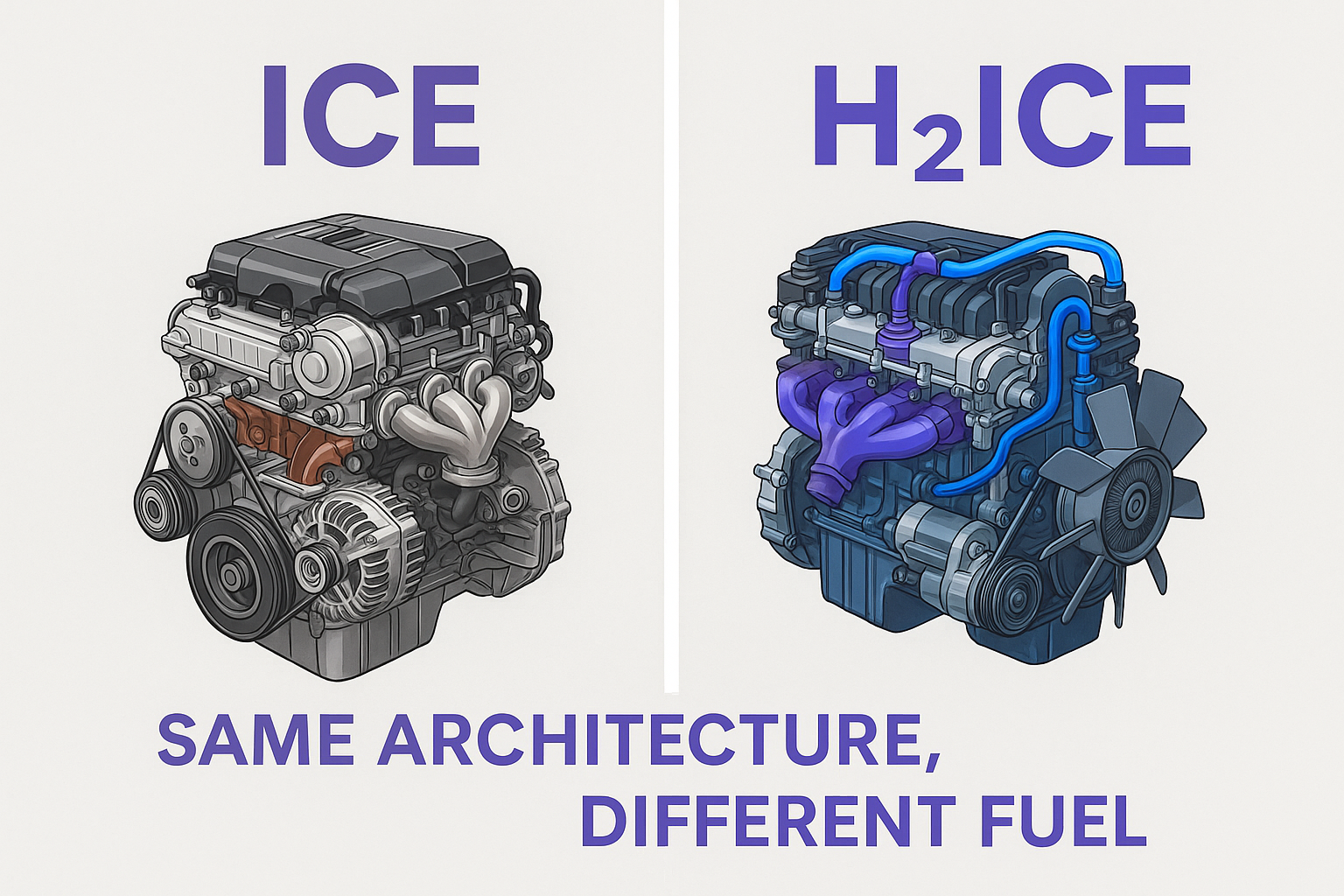

Against this backdrop, hydrogen combustion engines (H2ICE) are re-emerging as a credible middle-ground technology: low-tailpipe CO₂, rapid refuelling, and most importantly for the motor trade, a powertrain architecture based on familiar internal-combustion foundations.

What Makes Hydrogen Combustion Different?

Hydrogen internal combustion engines still use pistons, cylinders, crankshafts and mechanical timing. From a workshop perspective, this instantly places them closer to petrol and diesel ICE than to BEVs or fuel-cell vehicles. Much of the service logic is recognisable, though adapted for hydrogen storage, fuel delivery and ignition management.

For the repair sector, this means:

-

Training uplift, but not total retraining

-

Familiar diagnostic pathways

-

Mechanical repairability (unlike sealed BEV battery packs)

-

Less dependence on OEM-locked software ecosystems

-

Faster turnaround in many cases

In other words, the technology is new, but the skills base is not being torn up and rewritten.

Why Interest in Hydrogen Is Growing Again

The industry’s quieter shift back toward hydrogen combustion is not just technological, it is also economic and operational.

1. EV Practicalities Are Becoming Hard to Ignore

Workshops are now required to perform high-voltage risk assessments, 4-hour quarantines, multi-hour power-down and reinstatement, and full pre- and post-repair diagnostic sweeps on EVs. These add cost, complexity and time to even relatively simple repairs.

Insurers feel the pressure too: extended key-to-key times, high OEM part prices, restricted repair networks and total loss frequency that continues to climb.

2. Running Costs for Drivers Are Increasing

For private and fleet users, the original cost-benefit equation for EVs has shifted. Rising tariffs, the removal of incentives, increasing BIK for many company EVs, and ongoing congestion and ULEZ charges all reduce the financial appeal.

Hydrogen combustion avoids many of these issues. Refuelling is quick, weight is lower than large battery packs, and many existing ICE components and supply chains remain usable.

3. Repairability Is Better Aligned with Today’s Motor-Trade Realities

One of the biggest challenges facing the repair sector is the reduced repairability of BEVs. Large structural battery packs, parts availability and OEM-controlled methodologies often turn moderate damage into total losses.

Hydrogen combustion engines, by contrast, continue to offer:

-

Replaceable components

-

Mechanical serviceability

-

Less OEM-locked repair pathways

-

Reduced risk of irreparable battery damage

This makes H2ICE far easier to integrate into existing repair networks.

What This Means for the Motor Trade

For bodyshops, insurers, AMCs and engineering teams, hydrogen combustion could represent a welcome practical alternative, not a competitor to BEVs, but a complement that covers different needs.

Bodyshops

A technology curve that builds on existing ICE understanding rather than replacing it entirely. Training still required but no wholesale reinvention of workshop operations.

Insurers

Potential reduction in total loss frequency compared with BEVs, improved repair certainty, and less reliance on OEM battery-replacement rules.

Motor Engineers

A new set of methodologies to validate, but grounded in familiar systems. Hydrogen storage, fuel-system integrity and ignition management become key inspection points.

Fleets and Dealers

A zero-tailpipe-CO₂ solution that avoids the charging-infrastructure bottleneck and downtime issues associated with BEVs.

How Laird Will Support the Transition

As with all emerging propulsion technologies, Laird’s role is to interpret, validate and clearly communicate the engineering realities. Our teams already support EV, hybrid, ADAS and advanced structural repair decision-making, and hydrogen combustion engines naturally become part of this expanding portfolio.

We will continue to provide:

-

Independent engineering opinions grounded in current methodology

-

Clear, defensible repair vs total-loss analysis

-

Training and awareness for clients on new technology trends

-

Transparent reporting that reflects real-world repair and safety considerations

The future of propulsion will not be a single technology. It will be a blend. Battery-electric, hydrogen fuel-cell and hydrogen combustion will all play a role, and the motor trade must be ready to handle each confidently and efficiently.

Hydrogen combustion engines remind us that innovation does not always mean abandoning what came before. Sometimes, it means evolving it.

The Motor Trade Should Pay Attention Now

Hydrogen combustion engines might not yet dominate private-car showrooms, but change is accelerating. The win for repairers, claims engineers and workshop operators is in being proactive rather than reactive. Those who treat hydrogen ICE systems as tomorrow’s problem risk being ill-prepared when they start appearing in mainstream fleets or used-vehicle valuations.

For Laird’s clients, insurers, AMCs, repair networks and solicitors, being ahead of the curve means better repair-cost control, clearer methodology, fewer disputes and stronger defensibility across claims. Our role will be to help you interpret the technology, benchmark the processes, identify when hydrogen systems contribute to cost or complexity and ensure that every assessment is based on accurate methodology and modern understanding.